Control & LV Panel Manufacturing

- Home

- Control & LV Panel Manufacturing

Company Profile

Beginning with the manufacturing of Control Panels, we have steadily evolved with time and technology and have significantly expanded our operations. Today, we manufacture and export a complete range of all control panels.

AET believes in co-operation. The friendly and pleasant working atmosphere at AET, does business with company a please to the customers. The company’s continuous investment in technology and training, it’s dedication to total quality management in all disciplines from research and development to marketing, from manufacturing to after sales services, have created competitive advantage for the company.

Services & Deliverable

- WHY US

- VISION

- SERVE

- PANEL MANUFACTURING

- INDOOR PANEL

- Customized engineering solution.

- Extensive research before the development of product.

- Cost effective and type tested systems.

- Product development on latest technology.

- Quick Delivery within the stipulated time.

To become the leading System Solutions Company for Automation and control Panel Technology products and services in the region. While, building long-term relationships with our clients by providing them with state-of-the-art products and services related to the Automation solutions Industry

- Indoor Panel

- Outdoor SS Panel

- NEMA 4 Panel

- NEMA 4X Panel

- Explosion Proof Panel

- DDC Panels

- MCC Panels

- BMS Panels

- PLC Panels

- VFD Panel

- PD Panels

- LCP and LCS Panels

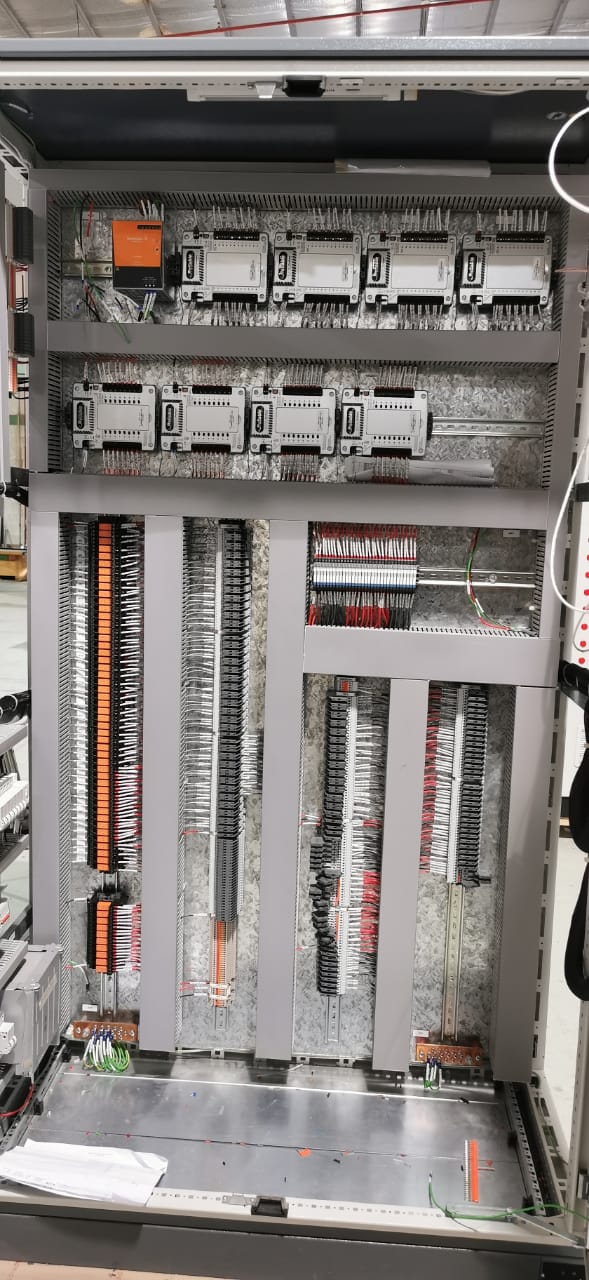

DDC DIRECT DIGITAL CONTROLLER

Operating Principles of DDC

Benefits of Direct Digital Control Systems

- Respond quickly to environmental changes, helping maintain more stable temperatures and, ultimately, better occupant comfort year-round

- Boost energy efficiency through programmable operations sequences

- Keep operating costs down by ensuring HVAC systems are running at peak efficiency at all times

- Reduce workloads by automating basic lighting and HVAC processes according to a set schedule

- Assist with diagnostics, reducing downtime and alerting you when preventative maintenance is necessary

- Simplify retro-commissioning, as individual equipment and systems can be swapped out without expensive infrastructural upgrades

DDC or Direct digital controller usually has the followings features

- The Analogue Inputs is to monitors the fields sensors values.

- Digital Inputs to monitors the on/off status from switches/contactors.

- The analogue output is to control the field actuators devices.

- Digital Output is to control relay or provide low voltages.

- DDC must have internal ROM/RAM to store control logic and sensor values.

- It must have networking protocols inbuilt to transfer the data between the devices.

- Modern DDC controller should have the capability to implement BACnet protocols for communication.

Variable Frequency Drive (VFD)

Local Control Panel (LCP)

Local Control Station (LCS)

OUTDOOR AND EXPLOSION PANEL

We are the leading Motor Control Center (MCC)Panel manufacturer in the latest design. The motor control center (MCC Panel) is the focal area for controlling electric motors. Which has a motor starter, wire, or electrical switch and is forcibly separated. A unique instrument called a motor control board is utilized to control motors in many ventures in numerous business and Industry applications different electric motors are required and it is normal alluring to control a portion of the motors.

- MCC Panel are with Fix / Draw Out type.

- MCC Panel with DOL, STAR-DELTA, RDOL, starters.

- MCC Panel are with various design like Single / Double Front, with DCS / Marshaling terminations.

- Facilities of different control voltage with control transformer control Bus With type-2 co-ordination wherever required.

CONSTRUCTION DETAILS

- Modular / Non- compartmentalized construction.

- Panel structure with MS CRCA/SS.

- Indoor / Outdoor type Structure.

- Single front/double front Operated.

- Provision for Extensible for future use.

- Provision of Rubber Gaskets to meet IP requirement like IP-42/52/54/55/65.

- Arrangement for heat dissipation by means of Exhaust Fan or Lowers.

- Electrical Grade Aluminum / Copper Busbar

- Main busbar chamber at top / bottom of the Panel

- Separate chamber for vertical dropper

- Busbar System design on basis of continuous Current rating and Fault level with stand capacity

- Allowable temperature rise as per IS 8623 or as per specifications

- Busbar supports of SMC/DMC Material

- Inspection of Fabrication structure for dimension as per approved G.A. drawing

- Inspection of Painting / Powder coating

- Electrical Grade Aluminum / Copper Busbar

- Main busbar chamber at top / bottom of the Panel

- Separate chamber for vertical dropper

- Busbar System design on basis of continuous Current rating and Fault level with stand capacity

- Allowable temperature rise as per IS 8623 or as per specifications

- Busbar supports of SMC/DMC Material

- Top / Bottom cable entry. Detachable gland plate for cable entry

A Building Management System is a computer-based system installed in buildings to manage and monitor equipment such as air-conditioning, heating, ventilation, lighting, power systems, security devices, IoT sensors, energy and gas meters.

Traditional BMS consists of servers, supervisory devices, field buses, controllers, inputs, and outputs. They are also known as Building Automation Systems (BAS).

A BMS connects the HVAC and different building equipment to work as one integrated unit. Ideally, they should centralize operations and make data easier to visualize using a user interface or console.

BMS has evolved into a series of incompatible components and impenetrable architectures. Their correct use saves 30% of the energy bill. BMS PANEL – BUILDIN

- Take control of your heating, ventilation and air conditioning with a custom designed and manufactured control system.

Control panels are an essential part of any BMS. Using modern, intelligent BMS control panel design and manufacture gives you simple and convenient

Control of temperature and energy efficiency throughout your building. Whether you need control panel design and manufacture for a completely new control system, or to be integrated into an existing one, our engineers will ensure its tailored perfectly to your building and your needs. From single units to multi-room controls across more than one building, we’ll give you complete control of HVAC plant.

- Our BMS control panel design and manufacture is:

- Designed specifically for your building and your control system

- Ready for immediate use

- Integrated design with existing control systems

- Compliant with all regulatory standards

PLC Introduction:

Local control panels are generally there to control the machine or equipment locally or remotely and installed in the close proximity of the controlled device.

A Local Control Panel is used in the automation of the machinery in motor control applications that are a part of water-based or Oil Based systems. This type of control panel consists of several power components that control the function of the pump motor, and also the various devices for operator control. To enable the automation of the machinery, additional sensors are employed. Pump Control Panels are available in a wide range of designs and configurations. They use distinct equipment like circuit breakers, switches, combination starters, vacuum and electromechanical contactors to control the various motor-controlled applications across water-based systems.

Most Pump Control Panels are used outdoors. In such instances, they are protected with the help of NEMA 3R or 4X rated enclosures. What purpose does this enclosure serve? It enables you to install the control panel near the water supply system like a well, and you needn’t worry about the control panel suffering water damage.

Others are designed according to the specific industrial requirements. There are specific applications that require a customized design, and such designs are developed to meet the preferences of the client.

- Universal Power Supply design – 58 264V AC 50/60 HZ, wide range power supply.

- All Core component used are from well-known global brands.

- The three-layer coating ensures the reliability in harsh environment.

- Flash memory data storage.

- 200 KHz high speed.

- Com port – 600 TVS, static surge protection.

- RS485 communication port ensures the reliability of communication in vibration.

- Reliable and stable high USB port for programing download.

High Speed Pulse Input:

External high speed pulse input encoder (AB phase) input, pulse + direction mode input; Maximum support for 200 KHz pulse signal input.

AB phase signal can support configurable frequency setting (i.e x1, x2 or x4)

PLC Host and Program Encryption:

For additional protection of the program, project building can be dedicated to the specified PLC model. PLC identification code and program identification code can be introduced. User can set the program identification code of the project and can set a PLC identification code for the PLC. So, the software will compare the program and can be executed to only designated PLC.

| S.No | 9 Com Number | Description | |

| 1 | 6000001838 | CONTROLLER; PROGRAMMABLE LOGIC; ENERGY M | 9COM |

| 2 | 6000000857 | MOTOR CONTROL CENTER; 16-SAMSS506 | 9COM |

| 3 | 6000000859 | PANELBOARD; LOW VOLTAGE, NONXPROOF | 9COM |

| 4 | 6000000885 | SWITCHGEAR, METAL-ENCLOSED LOWVOLTAGE | 9COM |

| 5 | 6000000897 | PANELBOARD,LOW VOLTAGE, EXPLOSIONPROOF | 9COM |

| 6 | 6000000898 | CONTROLGEAR, INDOOR LOW VOLTAGE | 9COM |

| 7 | 6000002723 | ESD; ELECTRONIC; PROGRAMMABLE | 9COM |

| 8 | 6000000936 | ADJUSTABLE FREQUENCY DRIVE 1KV AND ABOVE | 9COM |

| 9 | 6000013922 | CABINETS FOR PLC SYS (PLC INTEGRATION) | 9COM |

| 10 | 6000016361 | CABINET: DCS SYSTEM (ASSEMBLY AND TEST) | 9COM |